The present-day production of flake tobacco by Mac Baren does not differ significantly from the method used when flake tobacco came into being. The means may have become more advanced, but the principles have not changed – they remain just as they were 200 years ago.

In order to produce a good flake, we must be fully versed in the old traditions associated with flake tobacco. When a pipe smoker opens a tin of tobacco, he should be aware that the tobacco he holds in his hands is deeply rooted in these old traditions.

Below I will describe the entire process from the time the raw tobacco is stored until it reaches the tobacconists' shelves in small, square tins.

The first thing is to select the tobaccos that will make up the mixture. By using different types of tobacco, we can modify the taste experience of the finished tobacco mixture. Following the selection process the tobacco is threshed, i.e. the large stem is removed from the tobacco leaf. Sugar water is then added to the tobacco, exactly as the seamen used to do when the idea of flake tobacco was still developing.

The sugar water helps emphasise and underpin the natural taste nuances of the tobacco, and also keeps the tobacco moist. After 12 hours the tobacco is then dried, or cured, so that the sugar water that has not been absorbed by the tobacco evaporates. Then the final taste enhancer is added and the tobacco is ready to be pressed. Thus far the production of flake tobacco does not differ from the production of loose cut tobacco – but that all changes from here on.

Compressed

A good flake is characterised by the tobacco being firmly pressed together – and remaining pressed together. This result can only be achieved through the application of carefully tested technique and exceptional instinct on the part of our tobacco experts. We start by adding moisture, in form of steam, to the tobacco. This enhances the natural taste of the tobacco and ensures that it stays firmly pressed together. Given that tobacco is a natural product which differs from year to year and from region to region, the dexterity and experience of our tobacco experts is what determines how much moistness to add.

After the tobacco has been sufficiently moistened, it is packed into a holder measuring 40 x 40 cm and about 1 metre deep. Then a large plunger slowly presses the tobacco together to form a block of tobacco measuring 40 x 40 cm and about 3 cm in thickness. The block is laid on top of the other blocks, and it is important that they are kept under pressure until sufficient blocks have been produced to fill the tobacco press.

The Press

When 34 blocks of tobacco have been pressed, they are stacked in the tobacco press. The heavy covers are closed and screwed firmly in position, and a hydraulic press exerts 55 tons of pressure on the tobacco blocks. This may sound a lot – and it is. The blocks of tobacco are subject to this tremendous pressure for 12 hours, after which they are pressed so hard together that the degree of hardness is comparable to that of a wooden board. This slow, constant, strong pressure is the key to the finished flake tobacco not breaking apart and ensures that it retains its block form.

Storage

Now that the tobacco is pressed as hard together as possible, it is allowed time to mature and develop the last nuances of taste. The blocks are again stacked in a storage press, where the iron bars ensure that the pressure is sustained. During the next 30 days the taste develops and spreads evenly throughout the blocks, the taste nuances mix - and an exquisite smoking experience is close to being realised.

Cutting

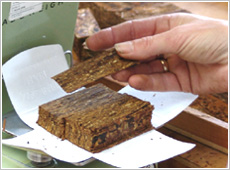

In days of old, seamen carried a pressed block of tobacco to sea and would cut a slice from the block to have a smoke. Today flake smoking is much easier for pipe smokers, as the tobacco is already cut into slices. First the outer edge is cut off all the way round, as the tobacco at the very edge of the block is a little loose. The rest of the block is then cut into 5 pieces each measuring 7 cm x 40 cm. These 5 pieces are then placed together and secured in a slicing machine to be cut into 1.4 mm thick slices – so-called flakes. After each cutting the result is studied and any flakes that are too loose are removed.

Packing

The actual packaging into tins is done by hand. In this way we can be 100% certain that the pipe smokers of the world get a flake tobacco that is consistent and undamaged. The packaging is the crown of this great work that began with selecting the right raw tobaccos, pressing them and generally handling the tobacco with the respect a good flake warrants. Finally, about 40% of the air in the tin is extracted to ensure that the flake tobacco stays fresh for decades.

Our production of flake tobacco is now complete and we are ready to entrust the tobacco to the real main person – the pipe smoker. We at Mac Baren hope that our tobacco will be enjoyed with due regard for the great amount of meticulous work that has gone into its production, combined with respect for the proud traditions of flake tobacco. But are these not just big words and empty talk? No; the extensive work that goes into the production process is a fact – and as far as the proud traditions behind the smoking of flake are concerned, I will go into this in more detail in the next section entitled: “How to fill a pipe with flake tobacco”.